Loading ...

• The operator must maintain a secure body position and

have a firm grip and footing when using this tool.

• This tool is not electrically insulated. Never use the

tool if there is any chance of it coming into contact with

live electricity.

CAUTION

Think safety! Safety is a combination of operator common

sense and alertness at all times when tool is being used.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

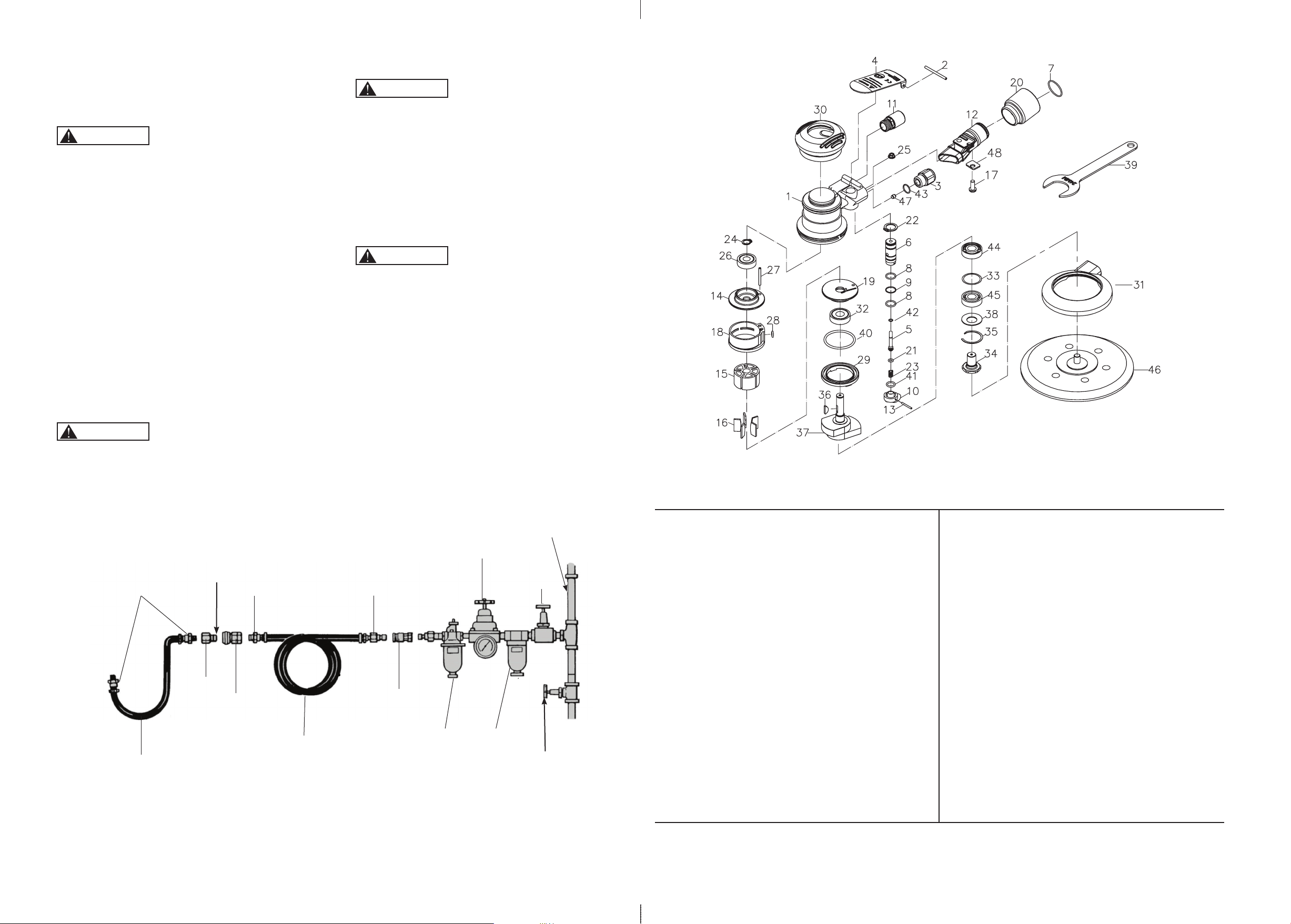

AIR SUPPLY SETUP AND CONNECTION

Refer to Figure 1

• Figure 1 shows the recommended air supply hook-up.

• The use of air line lubricators and air line filters is

recommended to prevent water in the line that can

damage the tool. Drain the air tank daily. Clean the

air inlet filter screen on at least a weekly schedule

to remove accumulated dirt or other matter that can

restrict air flow.

• The tool’s air inlet used for connecting an air supply has

a standard 1/4” NPT American thread.

• If an air line lubricator is not used, before operating the

tool add a few drops of Pneumatic Tool Oil into the tool

inlet. Repeat each hour of constant use.

CAUTION

This air tool requires lubrication BEFORE initial use and

before and after each additional use.

OPERATION

CAUTION

Never mount a grinding wheel on a sander. A grinding

wheel that bursts can cause very serious injury or death

when not properly guarded.

• Ensure the sanding pad is fixed securely to the tool.

Use the supplied wrench to hold the shaft nut in place

while turning the sanding pad clockwise to tighten and

counterclockwise to loosen.

• Select the correct 6" sanding disc for the job. Use 6"

hook and loop sanding disc.

• Connect to suitable air supply as recommended.

CAUTION

Risk of unsafe operation. Firmly grasp air hose with hand

when installing or disconnecting to prevent hose whip.

• Touch the sander lightly to the work and allow

the

sanding disc to cut. Take care when sanding around

sharp edges and surfaces to avoid the disc snagging,

the disc may be brought to an abrupt stop or

considerably slowed, causing the tool to kick in

the hands.

• Do not continue to use sanding discs that are worn or

clogged. Do not use undersized or oversized sanding

discs. The disc should be no more than 1/4" larger in

diameter than the sanding pad, and not smaller than the

sanding pad.

Key# Part# Description

1 AS631601 Housing

2 AS631602 Spring Pin (3*40L)

3 AS631603 Air Inlet

4 AS631604 Throttle Lever

5 AS631605 Shaft

6 AS631606 Bushing

7 AS631607 O-Ring (21.5*1.5)

8 AS631608 O-Ring 2 (10.7*1.5)

9 AS631609 O-Ring (10.5*1)

10 AS631610 Regulator

11 AS631611 Silencer

12 AS631612 Adapter

13 AS631613 Spring Pin (2*18L)

14 AS631614 Rear End Plate

15 AS631615 Rotor

16 AS631616 Rotor Blade(5)

17 AS631617 Screw (M5*12L)

18 AS631618 Cylinder

19 AS631619 Front End Plate

20 AS631620 Swivel Exhaust

21 AS631621 O-Ring (3.68*1.78)

22 AS631622 Retaining Ring (STW-14)

23 AS631623 Spring

24 AS631624 Retainer Ring

Key# Part# Description

25 AS631625 Nut (M5*0.8)

26 AS631626 Ball Bearing (6000zz)

27 AS631627 Spring Pin (3*28)

28 AS631628 O-Ring (5*2)

29 AS631629 Lock Ring

30 AS631630 Grip Hat

31 AS631631 Shroud

32 AS631632 Ball Bearing (6001zz)

33 AS631633 Washer

34 AS631634 Shaft

35 AS631635 Snap Ring

36 AS631636 Key

37 AS631637 Balancer Shaft

38 AS631638 Washer (3*13)

39 AS631639 Spanner

40 AS631640 O-Ring (39.4*3.1)

41 AS631641 O-Ring (8.8*1.7)

42 AS631642 O-Ring (2*1)

43 AS631643 O-Ring (13.5*1.5)

44 AS631644 Ball Bearing (6001)

45 AS631645 Ball Bearing (6001P)

46 AS631646 Pad (6")

47 AS631647 Stopper

48 AS631648 Washer

Figure 1

Tailpiece

Adaptor

Adaptor

Main Air

Hose

Whip Hose

Coupler

Coupler

Oiler

Filter

DRAIN

DAILY

Regulator

PIPES AND

FITTINGS

Stop Valve

Tailpiece

Adaptor

OIL HERE

DAILY

Tailpiece

Adaptor