Loading ...

Loading ...

Loading ...

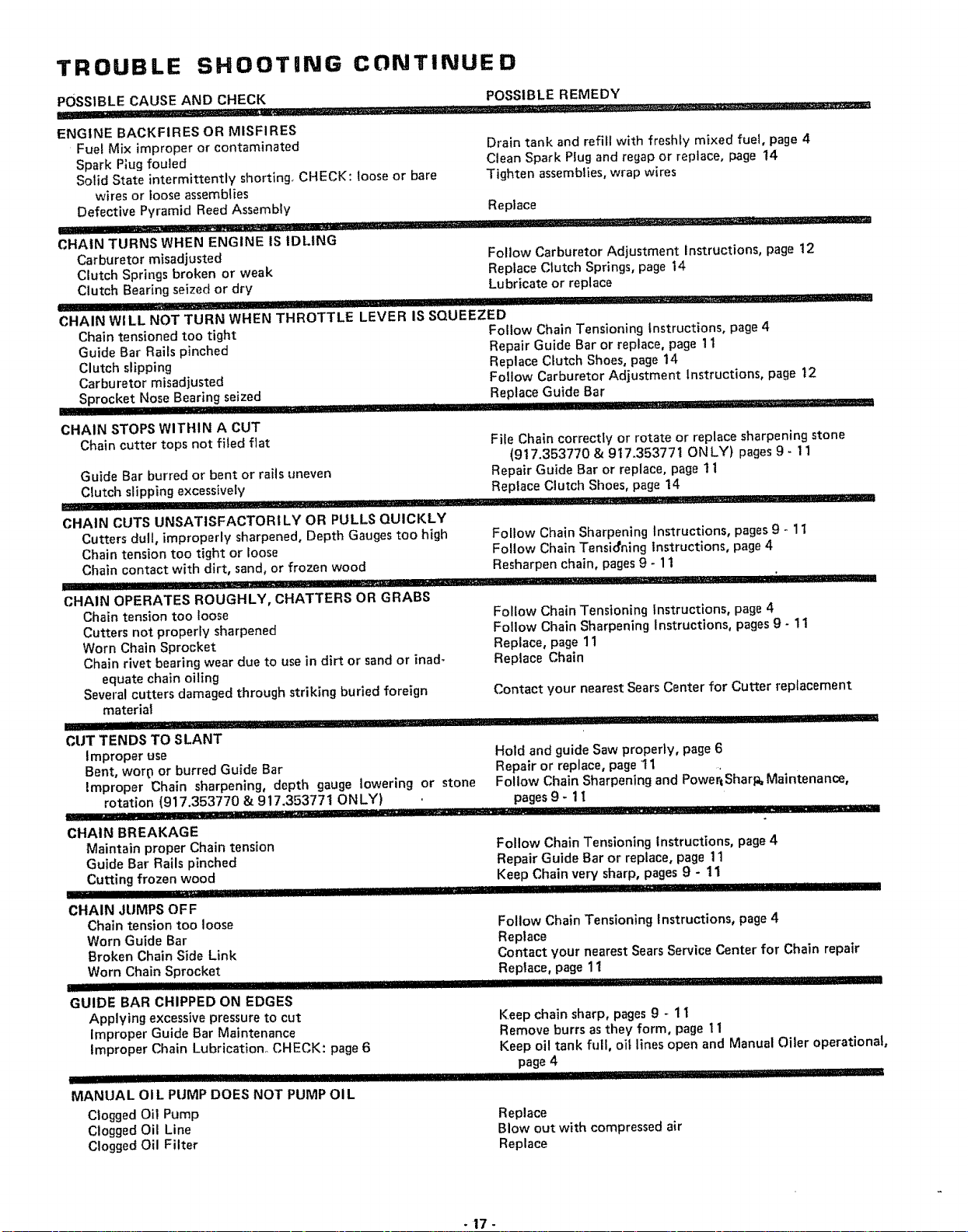

TROUBLE SHOOTING CONTINUED

POSSIBLE CAUSE AND CHECK POSSIBLE REMEDY

...... _ _ _=_:---_-_ :;_ _;z_: .... -.... " ----':--_-_ _ --__ .... :_===_ "_==-_-'_='_

ENGINE BACKFIRES OR MISFIRES

Fuel Mix improper or contaminated

Spark Plug fouled

Solid State intermittently shorting. CHECK: loose or bare

wires or loose assemblies

Defective Pyramid Reed Assembly

CHAIN TURNS WHEN ENGINE IS IDLING

Carburetor misadjusted

Clutch Springs broken or weak

Clutch Bearing seized or dry

I II!!111"[!_ _

Drain tank and refill with freshly mixed fuel, page 4

Clean Spark Plug and regap or replace, page 14

Tighten assemblies, wrap wires

Replace

Chain tensioned too tight

Guide Bar Rails pinched

Clutch slipping

Carburetor misadjusted

Spr0cket Nose Bearing seized

CHAIN STOPS WITHIN A CUT

Chain cutter tops not filed flat

Follow Carburetor Adjustment instructions, page t2

Replace Clutch Springs, page 14

Lubricate or replace

......... m ._.&m_ i iiiP

CHAIN WILL NOT TURN WHEN THROTTLE LEVER IS sQUEEZED

Follow Chain Tensioning Instructions, page 4

Repair Guide Bar or replace, page 11

Replace Clutch Shoes, page 14

Follow Carburetor Adjustment Instructions, page 12

Replace Guide Bar

J 'I I l'llr " I'I' iiii iiiiiii,,iiiiii ii iiii .................._,: .... i] 1,1, _!: _ ....................

File Chain correctly or rotate or replace sharpening stone

(9t7.353770 & 9t7.353771 ONLY) pages 9- 11

Guide Bar burred or bent or rails uneven Repair Guide Bar or replace, page 11

Clutch slipping excessively Replace Clutch Shoes, page 14

_- i i..... ..... ., iii .......... ;i';...... ii ' '-iiiii ;i"i ii ..... :- _-

CHAIN CUTS UNSATISFACTORI LY OR PULLS QUICKLY

Cutters dull, improperly sharpened, Depth Gaugestoo high

Chain tension too tight or loose

Chain contact with dirt, sand, or frozen wood

.......................................... -...... - '1 _ _ "'

CHAIN OPERATES ROUGHLY, CHATTERS OR GRABS

Chain tension too loose

Cutters not properly sharpened

Worn Chain Sprocket

Chain rivet bearing wear due to use in dirt or sand or inad_

equate chain oiling

Several cutters damaged through striking buried foreign

material

W'I'I ......

CUT TENDS TO SLANT

Improper use

Bent, wor_ or burred Guide Bar

Improper Chain sharpening, depth gauge lowering or stone

rotation (917.353770 & 917.353771 ON LY)

I1"1"1 ....- _ °_ .............

CHAIN BREAKAGE

Maintain proper Chain tension

Guide Bar Rails pinched

Cutting frozen wood

CHAIN JUMPS OFF

Chain tension too loose

Worn Guide Bar

Broken Chain Side Link

Worn Chain Sprocket

'11I'111111111IIi II

GUIDE BAR CHIPPED ON EDGES

Applying excessive pressureto cut

Improper Guide Bar Maintenance

Improper Chain Lubrication,, CHECK: page6

Follow Chain Sharpening Instructions, pages 9 - 1t

Follow Chain Tensio=ning Instructions, page 4

Resharpen chain, pages9 - 11

!!i'l' I'' 'll'l" II...... ;k .........._.....................

Follow Chain Tensioning Instructions, page 4

Follow Chain Sharpening Instructions, pages 9 - 11

Replace, page 11

Replace Chain

Contact your nearest Sears Center for Cutter replacement

........... . ................... ' ................I!llFII

Hold and guide Saw properly, page 6

Repair or replace, page 11

Follow Chain Sharpening and PowertShar_ Maintenance,

pages9 - 11

m ....

Follow Chain Tensioning Instructions, page 4

Repair Guide Bar or replace, page 11

Keep Chain very sharp, pages 9 - 11

,i H,IH',, ..........I

Follow Chain Tensioning Instructions, page4

Replace

Contact your nearest Sears Service Center for Chain repair

Replace, page 11

'!!! Iq" "1_/_ : ' '!! II ................

Keep chain sharp, pages 9 - 11

Remove burrs asthey form, page 11

Keep oil tank full, oil lines open and Manual Oiler operational,

page 4

III III III I II1" ,,1 ,i0 ..............................

Replace

Blow out with compressed air

Replace

II II IIII II IIIIII

MANUAL OIL PUMP DOES NOT PUMP OIL

Clogged Oil Pump

Clogged Oil Line

Clogged Oil Filter

- 17 -

Loading ...

Loading ...

Loading ...