Loading ...

Loading ...

Loading ...

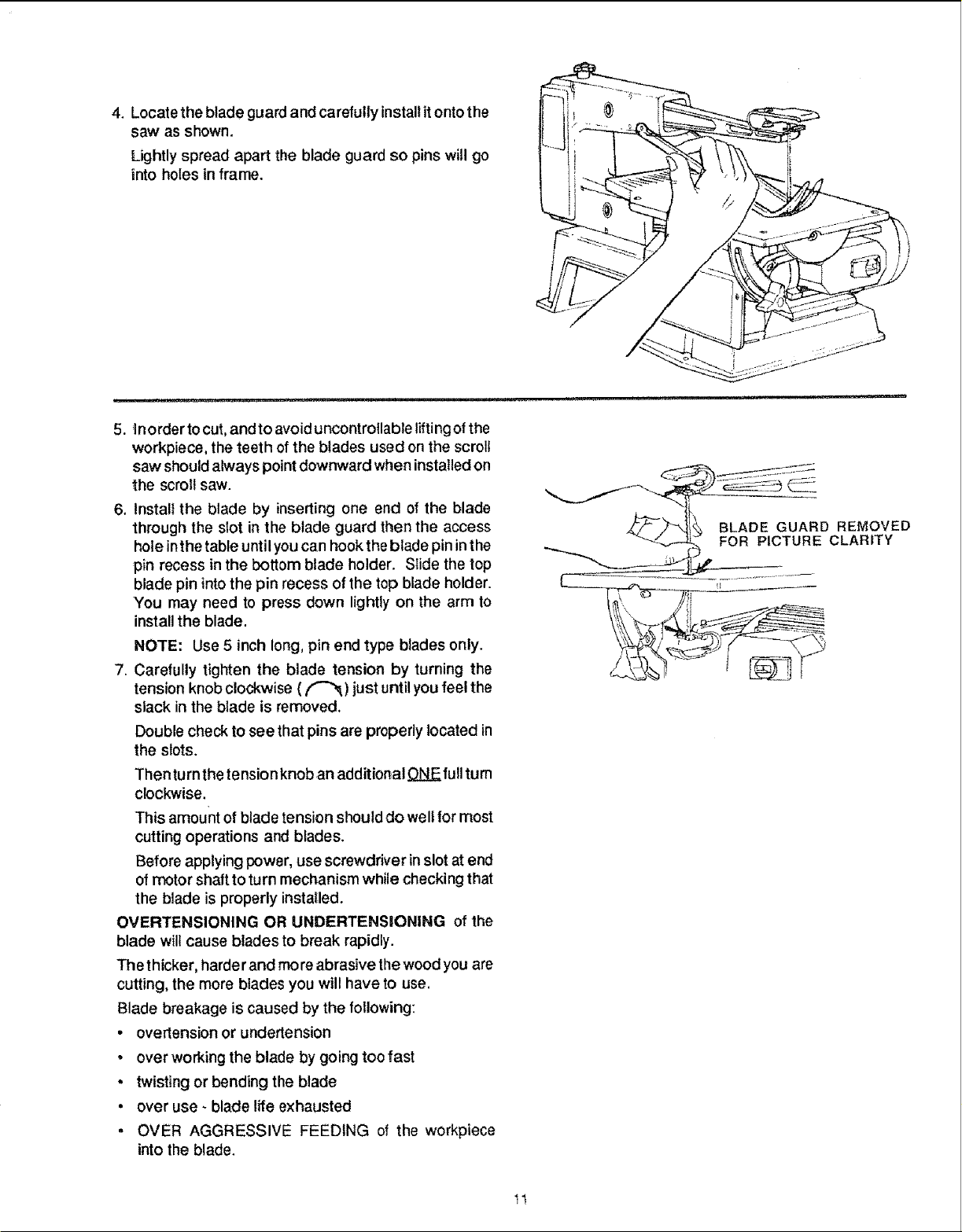

4. Locate the blade guard and carefully install it onto the

saw as shown.

Lightly spread apart the blade guard so pins will go

into holes in frame.

5. Inorder to cut, and to avoid uncontroUable lifting ofthe

workpiece, the teeth of the blades used on the scroll

saw should always point downward when installed on

the scroll saw.

6. Install the blade by inserting one end of the blade

through the slot in the blade guard then the access

hole in the table until you can hook the blade pin in the

pin recess in the bottom blade holder. Stide the top

blade pin into the pin recess of the top blade holder.

You may need to press down lightly on the arm to

install the blade.

NOTE: Use 5 inch long, pin end type blades only.

7. Carefully tighten the blade tension by turning the

tension knob clockwise ( f"--_,_) just until you feel the

slack in the blade is removed.

Double check to see that pins are properly located in

the slots.

Then turn the tension knob an additional D.E_ full turn

clockwise.

This amount of blade tension should do welt for most

cutting operations and blades.

Before applying power, use screwdriver in slot at end

of motor shaft to turn mechanism while checking that

the blade is properly installed.

OMERTENSIONING OR UNDEFITENSIONtNG of the

blade will cause blades to break rapidly.

The thicker, harder and mere abrasive the wood you are

cutting, the more blades you will have to use.

Blade breakage is caused by the following:

• overtension or undertension

• over working the blade by going too fast

- twisting or bending the blade

• over use - blade life exhausted

, OVER AGGRESSIVE FEEDING of the workpiece

into the blade.

11

Loading ...

Loading ...

Loading ...