Loading ...

Loading ...

Installation Instructions.

1. Dig the hole for the basin and the sub-base. The hole

must be deep enough so the top of the basin is flush with

the finished floor.

NOTICE: The sub-base should include 4” of sand or

gravel. The maximum diameter of rock should be 1/2”; 3/4”

maximum diameter pea gravel is recommended.

2. Level the sub-base out until it is smooth. Sharp rock can

damage the basin.

3. Reach into the inlet hole to retrieve the hardware kit.

Locate the cord grommet in the hardware kit.

4. Reach into the inlet hole again to pull the power cords

up through the cord grommet hole in the cover. Press

the cords into the cord grommet and install the grommet

in the cover.

5. Locate the inlet hub in the hardware kit, and snap it into

the inlet hole.

6. Install the basin on top of the sub-base.

7. Insert a 4” inlet pipe through the inlet hub. Insert it 2”

into the basin. Dish soap can be used to lubricate the

inlet hub. If necessary, file the sharp edges of the pipe to

prevent damage to the hub.

NOTICE: The inlet pipe should pitch down to the basin

inlet at 1/4” per foot. This will cause the water to run into

the basin.

8. Backfill around the basin with crushed rock, with a

maximum diameter of 1/2”, or use pea gravel.

9. Install a 1-1/2” discharge pipe into the 1-1/2” discharge

flange.

10. Install a 2” vent pipe into the vent flange. The vent pipe

must go through the roof of the building or it can be

connected to an existing vent pipe. The sump basin

must be vented.

NOTICE: Proper ventilation is needed to prevent

negative basin pressure and to provide air within the

basin.

11. Install a 1-1/2” check valve in the discharge pipe. Make

certain the flow indicating arrow points away from the

pump. This check valve will keep the water from running

back into the basin when the pump is not running.

NOTICE: To prevent pump contamination, clear basin

of any debris during or after installation.

12. Plug the pump into a properly grounded outlet.

13. Check the operation by filling the basin with water and

observing pump operation through one complete cycle.

Make sure no parts of the assembly interfere with the float.

OPERATION

Failure to make this operational check may

lead to improper operation, premature failure, and flooding.

NOTICE: The shaft seal depends on water for lubrication

and cooling. Do not operate the pump unless it is submerged

in water as the seal may be damaged if allowed to run dry.

Allowing the pump to run dry will void the warranty.

An automatic overload protector in the motor will protect

the motor from burning out due to overheating/overloading.

When the motor cools down, the overload protector will

automatically reset and start the motor.

If the overload trips frequently, check for the cause. It could

be a stuck impeller, wrong/low voltage, or an electrical failure

in the motor. If an electrical failure in the motor is suspected,

have it serviced by a competent repairman.

The pump is permanently lubricated. No oiling or greasing is

required.

NOTICE: The pump will not remove all water. For extended

operation, water depth must be at least 5” (13 cm) to prevent

motor overheating.

Airlocks

When a pump airlocks, it runs but does not move any water.

An airlock will cause the pump to overheat and fail. The

discharge pipe is plumbed with a predrilled anti-airlock hole.

Leakage from the anti-airlock hole is normal during pump

operation.

Float Switch – Operational Check

1. Fill the sump with the correct amount of water to check

the operation and tightness of the connections. During

the first automatic cycle, it may take 30 seconds or more

before the pump is primed and pumping. The pump will

start as indicated in the “Pump, Motor, Switch and Cord

Specifications” table on Page 2.

2. Check the turn-off position. The pump will stop

approximately as indicated in the “Pump, Motor, Switch

and Cord Specifications”.

3. If the pump does not operate, check the electrical service.

3

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

5596 0407

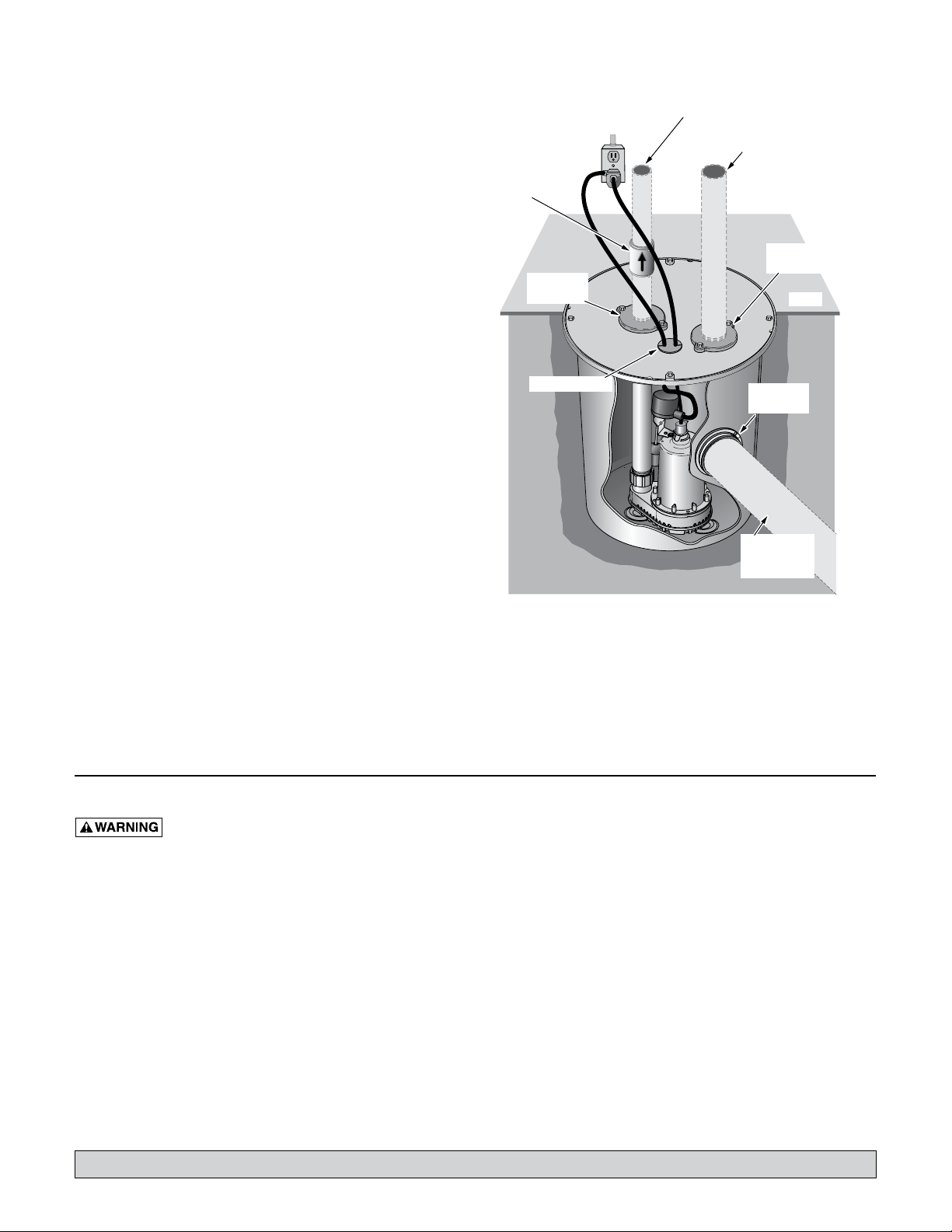

4" Inlet Pipe

Slope @ 1/4"

Per Foot

4" Snap-in

Inlet Hub

Cord Grommet

Discharge

Flange

Vent

Flange

Floor

1-1/2" Discharge

Pipe

Vent Pipe – Extend vent

through roof or connect

to existing vent.

Plug the Float Switch

into a Properly

Grounded Outlet.

Check Valve

Purchase check valve and inlet, vent

and discharge pipes locally.

Figure 1 – Typical Installation

Loading ...

Loading ...

Loading ...