Loading ...

Loading ...

Loading ...

E-3

English

5.1

Standards

The CTHK screw-in heaters are VDE certified and meet the

requirements of the following standards/guidelines:

DIN EN 60335-1

DIN VDE 0700-253

DIN EN 60529, degree of protection IP54

DIN 1988 technical regulations for

drinking water installations (TRWI)

EU directive 2006/95/EC (low voltage directive)

EU directive 1935/2004/EC (contact with food)

EU directive 97/23/EC (pressure equipment directive)

The plastic material of the connection casing fulfils the

requirements of § 5 Subsection 1 of the German foodstuffs and

consumer goods law and the recommendations of the German

federal office of consumer protection and food safety (KTW

certification).

5 Assembly, installation

and safety instructions

5.1 General installation and safety

instructions

ATTENTION!

Installation of the heating element and initial start-up must only be

performed by a qualified technician! Improper installation will void any

warranty claims.

The CTHK screw-in heaters must be installed by a technician in

adherence with the valid standards and installation regulations.

The following regulations must be adhered to:

The German Electrical Engineers’ Association (VDE)

stipulations and the regulations of the local utility company

The heating installation regulation (HeizAnl.V)

When used in pressure vessels: The AD instruction sheet

(workgroup pressure vessels) A3, Section 3.28

The DIN 1988 series standards

For closed water heaters, the arrangement of the fittings and

safety devices used must always be observed (acc. to

country-specific standards).

During operation, the electric heating element and the sensor

pipe must be completely immersed in water. The heat-induced

flow of water must not be obstructed.

The screw-in heater has a safety temperature limiter to prevent

further heating of the device when the water has reached a

maximum temperature of 95°C. According to DIN EN 60335-2-

21, the maximum water temperature may be up to + 20°C higher

(

⇒115°C) and thereby also has an influence on all the other

"components and installations" in the heat distribution system

and the generator circuit!

NOTE

When using a pressure relief system, it must be ensured that water is

able to drip from the outlet pipe of the pressure relief system, and this

pipe must be left open to the outside atmosphere; · the pressure relief

system must be operated regularly in order to remove limescale deposits

and to ensure that it is not blocked; an outlet pipe connected to the

pressure relief system at a constant downward angle must be installed in

a frost-free area.

Care must be taken to ensure that, in the event of a temperature

controller malfunction, the connection components (connection

pipes, safety valve combinations, etc.) will withstand the max.

possible controller temperature (according to the standard) and

further damage will be prevented.

In the case of very hard water, formation of limescale will limit the

function. Adequate measures must be taken, such as reducing

the temperature, installing a water softening system, or regularly

removing the limescale.

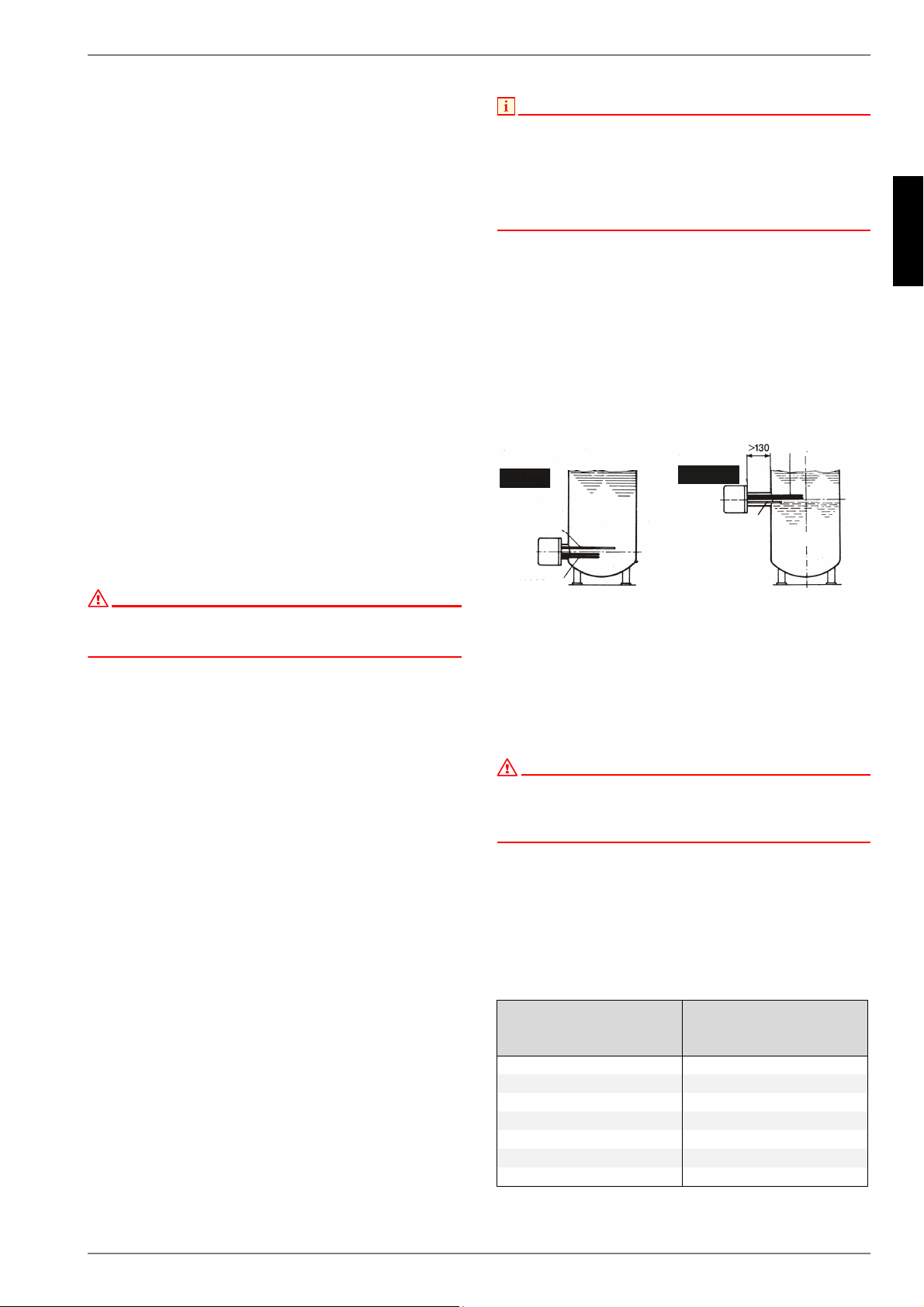

Mounting position:

In order to ensure that temperature sensor and heating element

reach far enough into the boiler, the R 1 ½" connecting sleeve of

the cylinder must not be longer than 130 mm.

In order to heat the entire contents of the boiler uniformly, the

screw-in heater should be installed as far down in the boiler as

possible.

A minimum distance (installation length + 100 mm) must be

maintained in front of the connecting sleeve for mounting, etc.

ATTENTION!

During installation make sure that the immersion pipe (temperature

sensor) is installed in the correct position. The immersion pipe must

always be mounted above (1 phase) or above and between (3 phases) the

heating element(s)!

Recommended fluid amounts

See the following table for the amount of fluid to be heated in

relation to the power consumption (acc. to VDE 0700 Part 73 §

7.12.1).

The specified amounts are minimum amounts. Deviations are

possible depending on the application. Tubular heating elements

must always be covered by a sufficient amount of fluid.

Nominal power

consumption

(W)

Amount of fluid (approx.)

(litres)

2000 5

3000 8

4500 12

6000 16

7500 20

9000 24

12000 32

&RUUHFW

,QFRUUHFW

7HPSHUDWXUHFRQWUROOHU

+HDWLQJHOHPHQW

7HPSHUDWXUH

FRQWUROOHU

+HDWLQJHOHPHQW

)ODQJHIUDPHWRRORQJ

DQGZHOGHGLQWRRKLJK

7HPSHUDWXUHFRQWUROOHU

XQGHUQHDWKKHDWLQJHOHPHQW

IULJLG]RQH

Loading ...

Loading ...

Loading ...