PROPEL Quick Install Guide

NOTE: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

STEP 1 - Install the header end bracket (split/twin doors)

Open up the end bracket and bolt together to form a right triangle. You’ll recognize the end bracket by the extra 4”

piece of punch angle bolted to it. Identify the center of the header over the door opening. Mount the bracket using the

hardware provided. Mount the bracket 3”-12” above the bottom edge of the jamb. Connect the sway brace to the End

Bracket and to the Header. If you have split/twin doors, you will have 2 end brackets at the center of the header.

STEP 2 - Install the header Intermediate Brackets.

These brackets are mounted at the same height above the bottom of the header as the End Bracket. Open the

intermediate bracket and bolt together as shown below. Evenly space the intermediate brackets along the header. For

most doors, you’ll mount an Intermediate Bracket every 6-7 feet from the End Bracket.

NOTE: I-beam headers may require that you disassemble these brackets and use the punch angle to create brackets

that mount directly to the trusses. See photo below.

HINT: You will save time and energy if you run the wire for the photocells as you are mounting these brackets. The

wire can be run through the holes in the punch angle brackets. Be sure the wire doesn’t hang down where it can

become caught in moving parts.

STEP 3 - Mount the Door Arms

Locate the door arm and the door arm hardware bag. install the upper gussets at the upper corner of the door. As

with the lower gusset, be sure the door is closed to ensure the gussets do not interfere with each other or, in the case

of single doors, with the building.

Note: If the inside vertical door support has ridges, you may need to grind them down so that the gusset is flush

against the door. Alternatively, use washers to shim out the gusset at the leading edge so that the rest of the gusset

lies flat. Open the door fully to ensure that the gusset does not hit the building as the door retracts. Screws along the

top edge of the gusset must be flush with the gusset or the gusset may hit the building when the door closes, causing

the motor to reverse the doors.

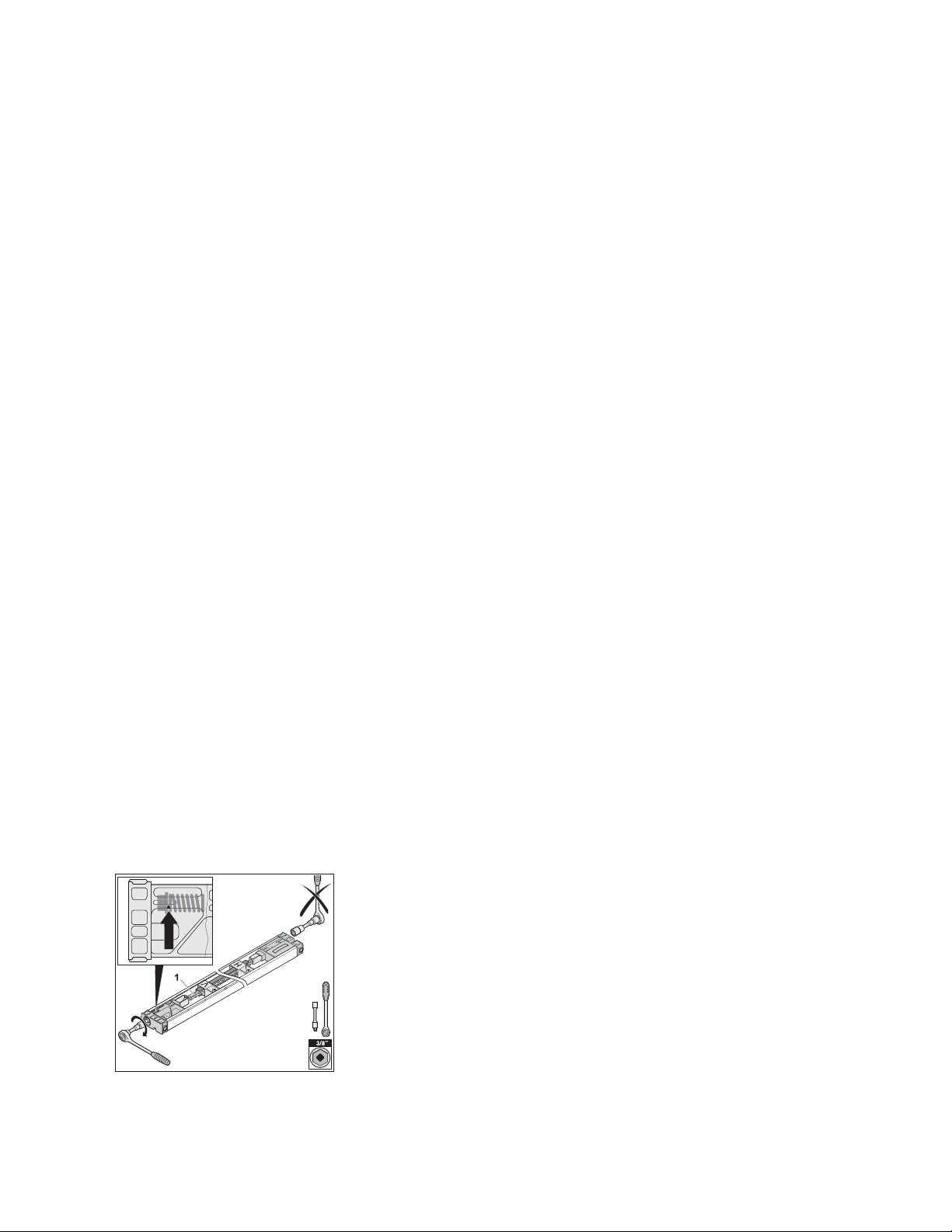

STEP 4 – Prepare the C-rail (drive track)

Rail pre-assembly

a. The chain (1) is inserted into the plastic chain channel (2). The chain channel guides the chain and also isolates

the chain from the C-rail (3). Please do not remove!

Rail mount bracket pre-assembly

b. Slide the ceiling bracket (3) onto the C-rail.

NOTE: The rail mount bracket will not slide over the connecting sleeve. Place the rail mount brackets on the

appropriate sections of track that align with the header brackets (see Step 8) before connecting the rail sections with

the connecting sleeve. You’ll want the ceiling brackets to be spaced 6-7 feet from the end of the assembled rail that is

opposite the motor.

c. Insert both C-rails into the connecting sleeve all the way to the stop position. On the C-rail end that is opposite the

motor:

d. Attach tensioner to chain and turn it by 90°

e. Insert slide-in part in the C-rail and place the tensioner into the opening of the slide-in part.

f. Place the washer and the spring on the tensioning bolt M8 x 80 mm and screw the tensioning bolt into the

tensioner (1) by hand.

18 en

9. Slide in the slide-in part (2) together with the chain (1).

Final position see graphic.

On the opposite side of the C-rail:

10. Attach tensioner (1) to chain (2) and turn it by 90°.

11. Insert slide-in part (3) in the C-rail (4) and place the ten-

sioner (1) into the opening of the slide-in part (3).

12. Place the washer (6) and the spring (7) on the tension-

ing bolt (8) M8 x 80 mm (8) and screw the tensioning bolt

into the tensioner (1) by hand.

13. Tighten the chain (1) using a 3/8“ socket wrench up to

the marking. Arrow has to line up with collar of the ten-

sioning bolt.

Caution

The pre-installed slide-in part on the opposite side has been

already pre-tensioned at the factory and must not be tight-

ened any further. Attempting to tighten further can damage or

destroy the tensioner.

14. To set the motor carriage into position (1) pull the emer-

gency release cord once (N). Then move the carriage

until it locks into place.

8. Installation

g. Tighten the chain (1) using a 3/8“ socket wrench up to the marking. Arrow has to line up with collar of the

tensioning bolt.

h. To set the motor carriage into position pull the emergency release cord once. Then move the carriage until it locks

into place.

1

Loading ...

Loading ...

Loading ...