Loading ...

Loading ...

Loading ...

MINI ULTRA ELECTRIC BOILERS Installation and operating manual (Revision: May 2015)

20

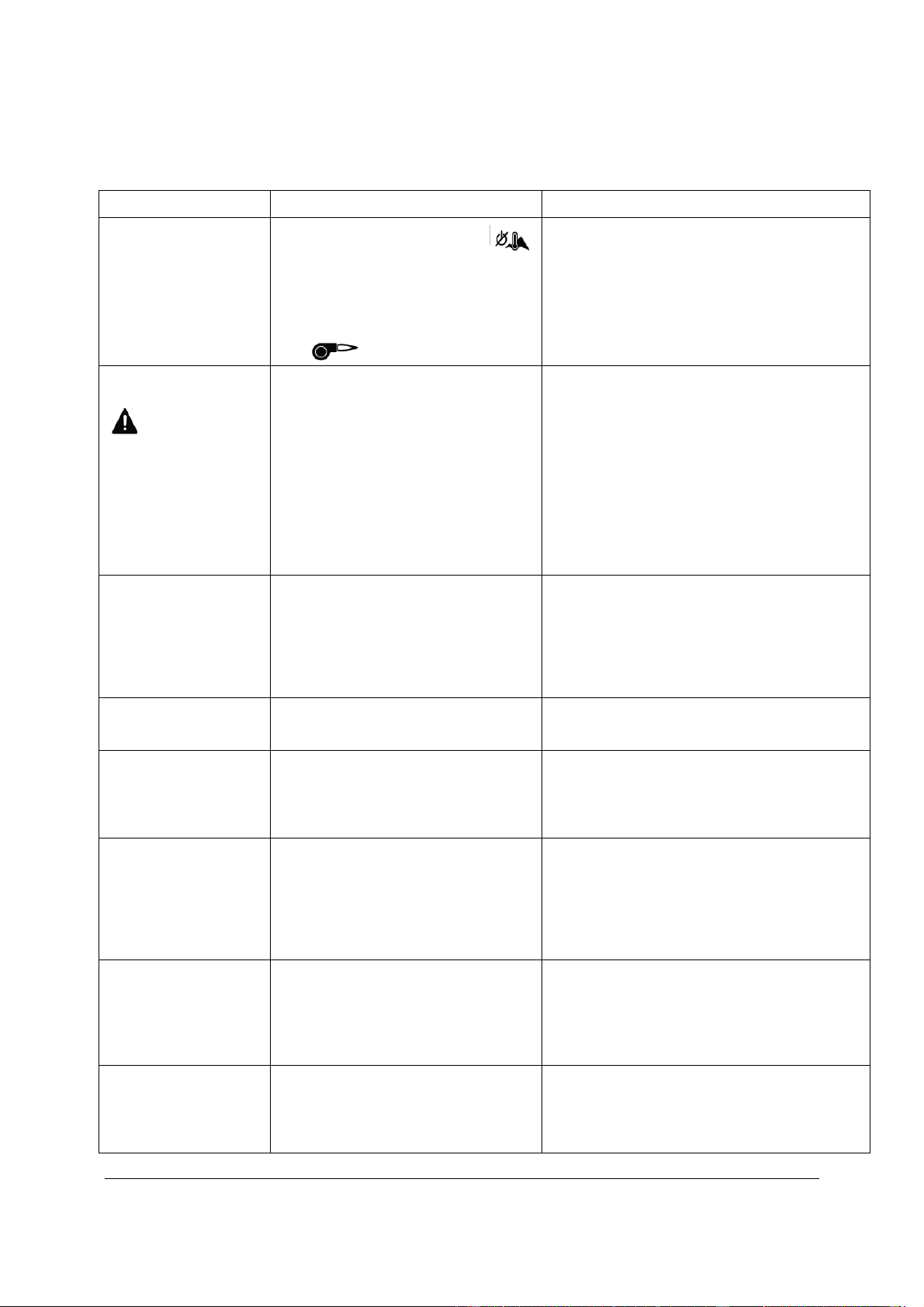

Section 7 : TROUBLESHOOTING

PROBLEM CAUSES SOLUTION

The display shows

---

in “TARGET TEMP”

-There is no heating demand

-When the outdoor sensor

is used and the icon is shown, the

outside temperature is above the

boiler shut down setting.

-The switch located on the back of the

controller is set to “Bi-Energ” and the

icon is shown.

-Generate a heat demand

-Temporarily increase the value of this setting

on the controller configuration.

-Set the switch to “Elect”

The display shows

“Er1”

and the icon

is displayed.

The controller is not detecting the

presence of the outdoor sensor.

-Make sure that the sensor cable connected to

the unit is not in short or open circuit. Do not

install a jumper between S1-S1 when the

sensor is not required.

-Check the resistance value (ohms) of the

sensor. It should correspond to the value

shown on the table below otherwise it should

be replaced.

Check for proper connection of the wires

inside the boiler connected to S1S1 and at the

controller terminals.

The display shows

“

Er2

” and blinks

The controller is not detecting the

presence of the boiler temperature

sensor.

-Check the state of the sensor located in the

immersion well located at the top of the

electrical element compartment.

-Check the resistance value (ohms) of the

sensor. It should correspond to the value

shown on the table below otherwise it should

be replaced.

Stage 2 is ON but not

Stage 1

There is no problem. A rotation of the

stages is provided to allow an equal

time of operation of the stages.

The boiler target

temperature does not

change when the

outdoor temperature

varies.

The outdoor sensor has not been

detected when the power has been

applied to the unit.

Check the connection of the outdoor sensor to

terminals S1S1. Turn OFF the power to the

unit for 5 sec. and set it back ON.

The boiler water

temperature at the

outlet of the unit

“BOILER T

0

”does not

get to the “BOILER

TARGET T

0”

-The room thermostat is not in

constant demand.

-Some heating elements are defective

-The total capacity of the boiler is

being used by the heating distribution

system at this temperature.

-Adjust the thermostat anticipator (If available)

to obtain longer operating cycles

-Replace defective elements

-If a higher boiler water temperature is

required to satisfy the heat demands of the

thermostats, a boiler having a larger capacity

is required.

Boiler stays in demand

even when the

thermostat is not in

demand.

(Systems with more

than one thermostat)

-On systems with electric zone

valves, one or many end switches

included in the valve is defective.

-A jumper has been installed on

terminals W&R of the boiler.

-Change defective end switch.

-Make appropriate connections as shown in

fig.6

An overheated plastic

odour is released from

the boiler

Turn the power OFF to the boiler.

Open the front and left side panel of

the boiler. Check the components and

electric wires for indications of

overheating.

Replace overheated components and check

supply voltage to the boiler.

Loading ...

Loading ...