Loading ...

Loading ...

Loading ...

en Installation

14

Exhaust duct

Note: The device manufacturer does not assume any

warranty for complaints attributable to the pipe section.

■ The device achieves its optimum performance by

means of a short, straight exhaust air pipe and as

large a pipe diameter as possible.

■ As a result of long rough exhaust air pipes, many

pipe bends or pipe diameters that are smaller than

150 mm, the optimum extraction performance is not

achieved and fan noise is increased.

■ The pipes or hoses for laying the exhaust air line

must consist of non-combustible material.

Round pipes

An inner diameter of 150 mm, but at least 120 mm, is

recommended.

Flat ducts

The inner cross-section must correspond to the

diameter of the round pipes.

dia. 150 mm ca. 177 cm

2

dia. 120 mm ca. 113 cm

2

■ Flat ducts should not have any sharp deflections.

■ Use sealing strips for deviating pipe diameters.

Connecting the appliance to the power

supply

Connecting the air extractor

Note: If using an aluminium pipe, smooth the

connection area beforehand.

1. Attach the air extractor pipe directly to the air-pipe

connector.

2. Connect to air extractor opening.

3. Seal the joints appropriately.

Connect the power supply

1. Plug the mains plug into the earthed socket.

2. If a fixed connection is required, please follow the

instructions in the Electrical Connection section.

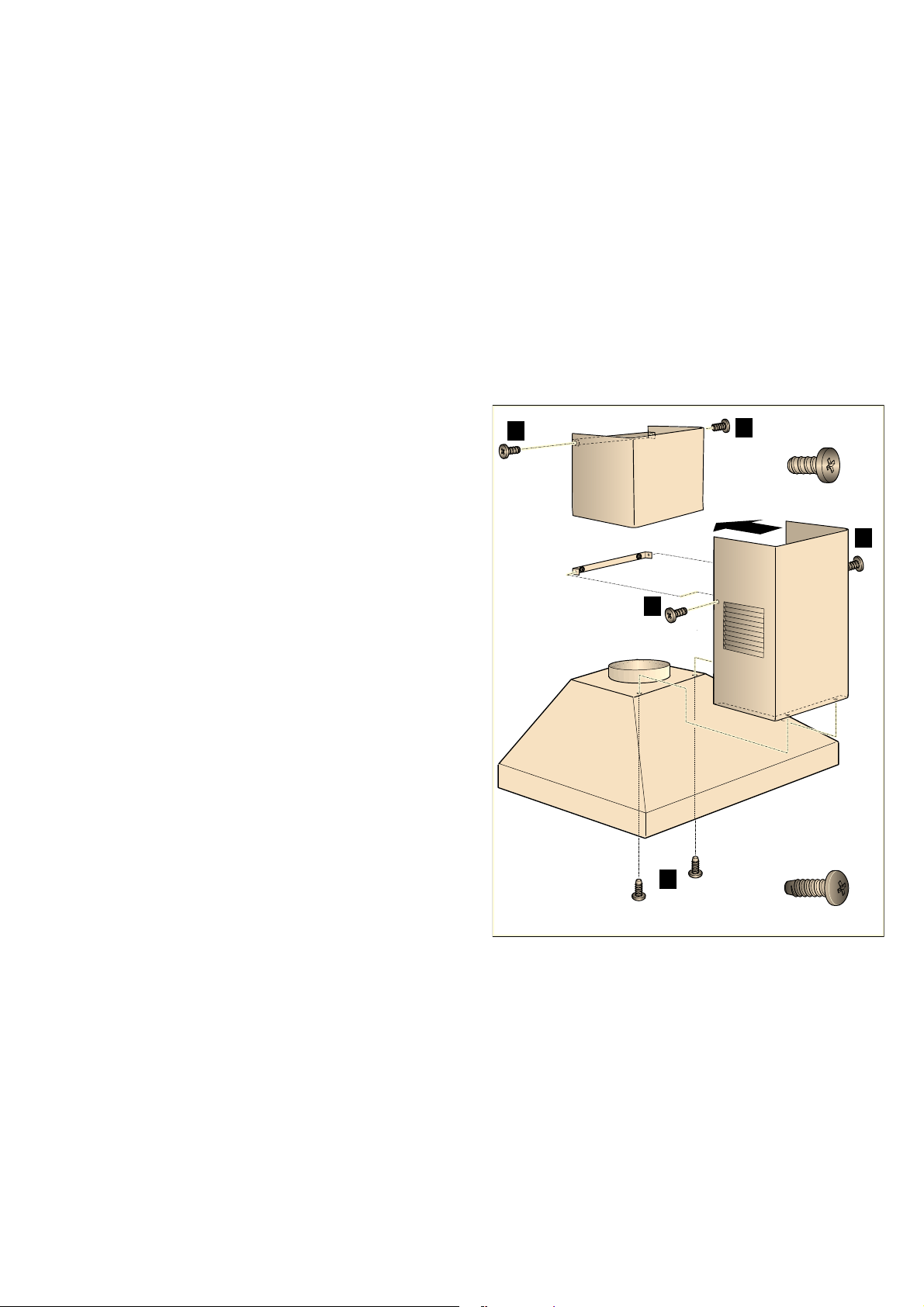

Attaching the flue duct

:Warning – Risk of injury!

Components inside the appliance may have sharp

edges. Wear protective gloves.

1. Separate the flue ducts.

To do this, remove the adhesive tape

2. Remove the protective foil from both flue ducts.

3. Screw the upper flue ducts to the sides of the fixing

bracket using two short screws. ¨

4. Place the lower flue ducts on the appliance and fix in

place using two long screws on the bottom of the

appliance. ©

5. Screw the lower flue duct to the sides of the fixing

bracket using 2 short screws. ª

Note: Align the flue duct before tightening the 2

screws.

[

[

$

$

%

&

&

Loading ...

Loading ...