Loading ...

VENTiLATiNG AND WiRiNG

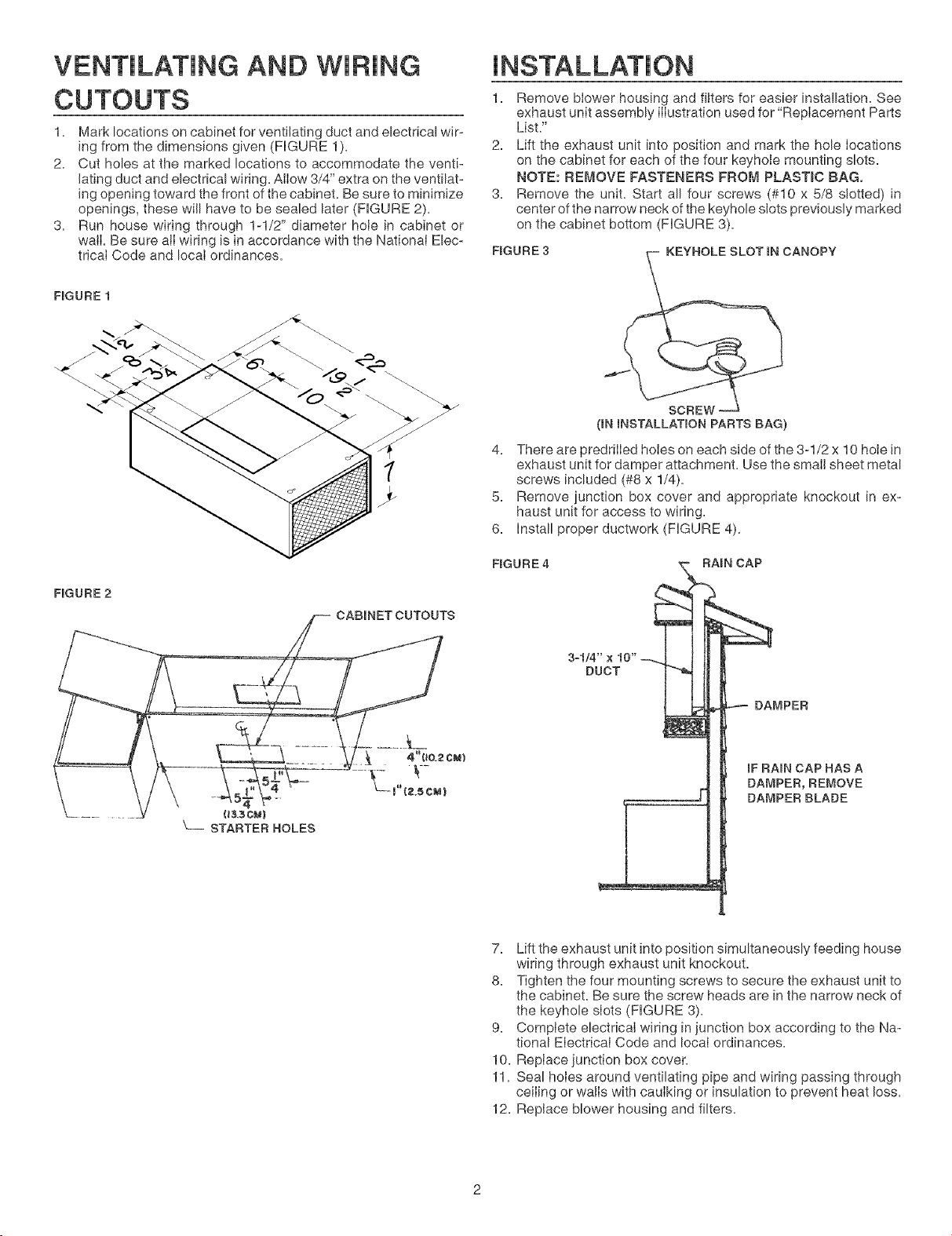

1. Mark locations on cabinet for ventilating duct and electrical wir-

ing from the dimensions given (FIGURE 1).

2. Cut holes at the marked locations to accommodate the venti-

lating duct and electrical wiring. AiIow 3/4" extra on the ventilat-

ing opening toward the front of the cabinet. Be sure to minimize

openings, these will have to be sealed later (FIGURE 2).

3. Run house wiring through 1-1/2" diameter hoIe in cabinet or

waII. Be sure alI wiring is in accordance with the NationaI Ebc-

tricaI Code and IocaI ordinances.

1. Remove bIower housing and fiiters for easier installation. See

exhaust unit assembly illustration used for "Replacement Parts

List."

2. Lift the exhaust unit into position and mark the hole locations

on the cabinet for each of the four keyhole mounting slots.

NOTE: REMOVE FASTENERS FROM PLASTIC BAG.

3= Remove the unit. Start all four screws (#10 x 5/8 shotted) in

center of the narrow neck of the keyhole slots previously marked

on the cabinet bottom (FIGURE 3).

RGURE 3 KEYHOLESLOTINCANOPY

FIGURE 1

FmGURE 2

1

CABINET CUTOUTS

SCREW

(iN iNSTALLATiON PARTS BAG}

4. There are predriIIed holes on each side of the 3-1/2 x 10 hole in

exhaust unit for damper attachment. Use the smaII sheet metal

screws included (#8 x 1/4).

5. Remove junction box cover and appropriate knockout in ex-

haust unit for access to wiring.

6. install proper ductwork (FIGURE 4).

RGURE4

7. Lift the exhaust unit into position simultaneously feeding house

wiring through exhaust unit knockout.

8. Tighten the four mounting screws to secure the exhaust unit to

the cabinet. Be sure the screw heads are in the narrow neck of

the keyhole slots (FIGURE 3).

9. Complete electrical wiring in junction box according to the Na-

tional EIectrical Code and IocaI ordinances.

10. Replace junction box cover.

11. Seal holes around ventilating pipe and wiring passing through

ceiIing or walIs with cauIking or insulation to prevent heat loss.

12. Replace blower housing and filters.

Loading ...

Loading ...

Loading ...