Loading ...

Loading ...

Loading ...

TROUBLESHOOTINGGUIDELINE

ALWAYSDISCONNECTTOOLFROMAIRSUPPLYANDREMOVEFASTENERSFROM

MAGAZINEPRIORTOPERFORMINGREPAIRSORCLEARINGJAMS

Page8

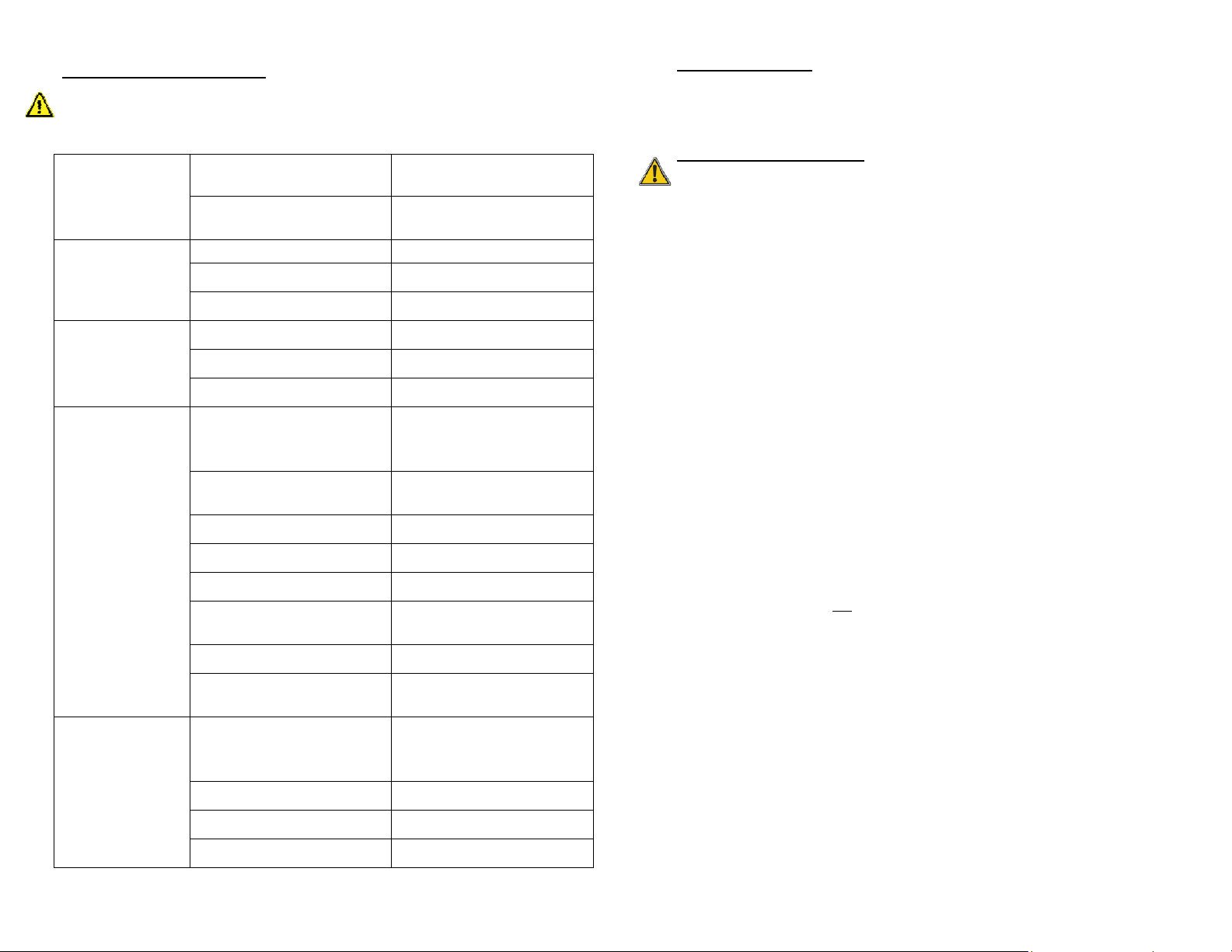

SYMPTOM CAUSE FIX

Triggervalve

housing/stem

leaksair

1.O‐ring/sealscutorworn 1.ReplaceO‐ring/seals

2.Valvepackingwornout 2.Replacetriggervalve

assembly

Caporexhaust

coverleaksair

1.Capsealwornout 1.Replacecapseal

2.Boltsoncaploose 2.Tightenthe

bolts

3.Exhaustvalvewornout 3.Replaceexhaustvalve

Noseleaksair

1.Boltsonnoseloose 1.Tightenthebolts

2.Bumperwornout 2.Replacethebumper

3.Gasket/o‐ringcutorworn3.Replacegasket/o‐ring

Lackofpoweror

nofuncon

1.Airpressure

insufficient

1.Adjustairpressure

properlybetween70‐120

PSI

2.Lackoflubricant

2.Lubricatepistono‐ring,

cylinderorexhaustvalve

3.Cylinderspringbroken 3.Replacecylinderspring

4.Wornheadvalveo‐rings 4.Replaceo‐rings

5.Headvalvestuck 5.Disassembleandlubricate

6.Blockedexhaust

6.Checkbumper,head

7.Triggerassemblyworn 7.Replacetriggerassembly

8.Drivernotfunconing

properly

8.Disassembledriverto

clean

Nailsjammed

1.Inwrongspecificaon

bentorpoorqualityofthe

nails

1.Applycorrect

specificaonandqualified

nails

2.Driverbladewornout 2.Replacedriverblade

3.Boltsloose 3.Tightenthebolts

4.Driverguidewornout 4.Replacedriverguide

EXPLOSIONHAZARD

Donotoperatetoolinexplosiveatmospheres,suchasinthepresenceofflammableliquids,

gasesorcombusbledust.Sometoolswillcreatesparksthatcanbeanignionsourcefor

afireorexplosion.

AIRSUPPLY&CONNECTIONS

Donotuseairsupplypressuresthatexceed120PSI

(8.28baror8.4kg/mm’)

Useonlyclean,regulatedcompressedairasapowersourceforthistool.Donotusebole

gases,combusblegasesoroxygenasapowersourceforthetoolasthetoolmayexplode.

Recommendedoperangpressureis80to110p.s.i.(8.28baror8.4kg/mm’)Donotexceed

therecommendedmaximumoperangairpressureas toolwearwillbegreatlyincreased.

Theairsupplymustbecapableofmaintainingtheoperangairpressureofthetool.Pressure

dropsinthe

airsupplycanreducethetool’sdrivingpower.

Ifaregulatorfails,thepressuredeliveredtoatoolmustnotexceed1.5mesthemaximumair

pressureor200psig(13.8bar)whicheverisgreater.

Useapressureregulatortoallowvisualinspeconoftheairpressurebeingdeliveredtothe

tool.

AirHoses

Useairhosesthathaveratedpressuresofupto150%ofthemaximumpressurethatcanbe

generatedbythepowersource.Thesupplyhoseshouldcontainafingthatwillprovide

quickdisconnecngfromthemaleplugonthetool.

Fings

Installamalepneumacfingontotherearcapofthetool,ensuringthatthefingallows

thetooltoexhaustanyairinthetoolwhentheairhoseisdisconnected.

Donotusefingsthatwillnotallowthetooltoexhaustwhentheairsupplyisdisconnected.

Lubricaon

Useairlinelubricators.Iflubricatorsarenotavailable,orifhoselengthsexceed10feet,

add2dropsofnon‐detergent20weightoildailyintotheairinletofthetool.

Addtwodropsofnon‐detergent,20weightoilintothemalefing.

ColdWeatherStorage

Removeallfastenersfromthetool.

Neverstorethetoolincoldweatherenvironmentsforanyduraonofmeasanyfrost

oriceformaoninthetoolwillcausetoolfailures.

Forprolongedstorage,addtwodropsofoiltotheairinletofthetoolpriortodisconnuing

use.Alsocleantheexteriorofthetoolwithamildsolvent.

Page5

Loading ...