Loading ...

Loading ...

Loading ...

10 11

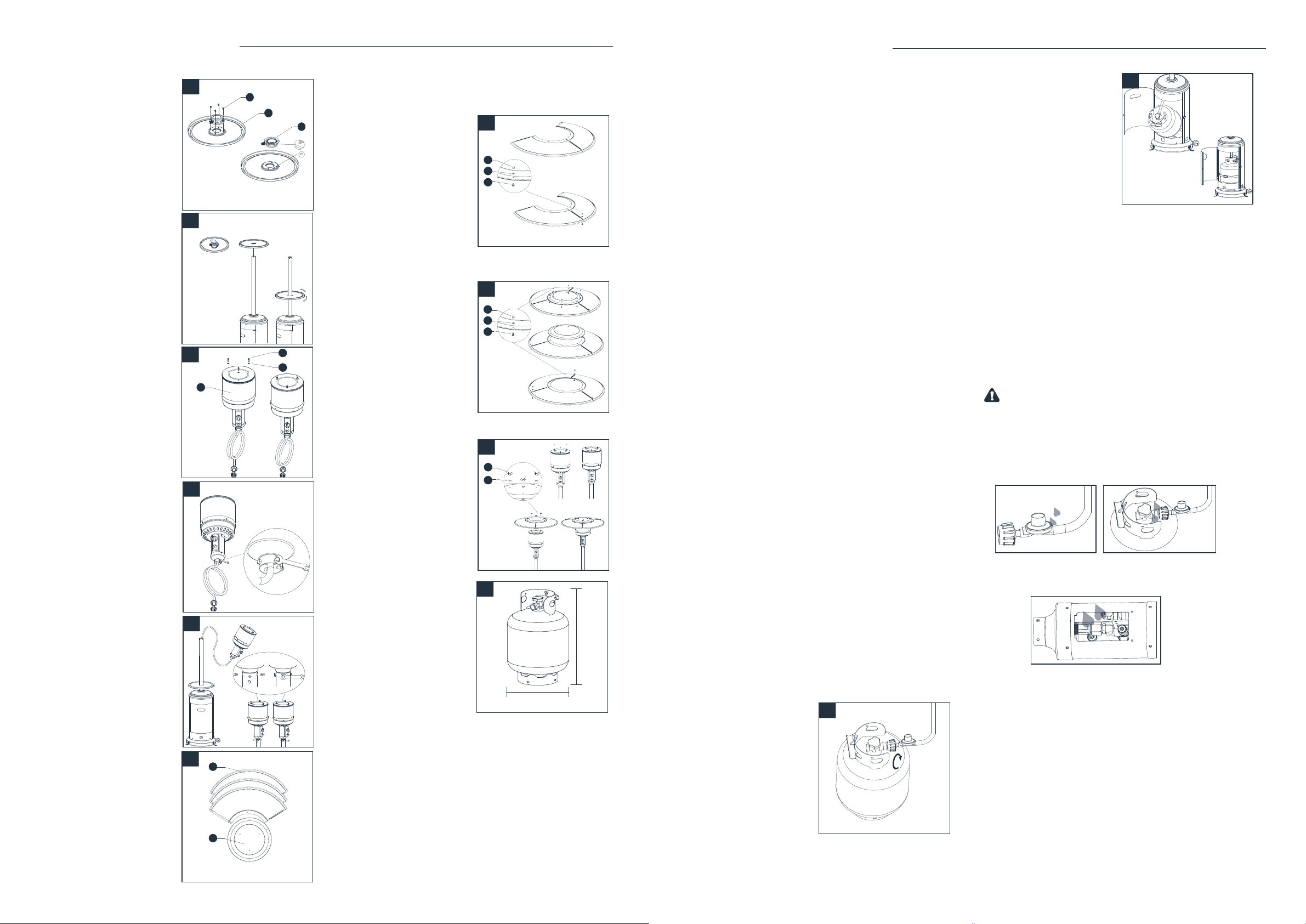

5. Beverage table installation

5-1. Revised the table

(D). Attached the table

connector (E) to the table,

secure them with four M5 X

8 screws (CC).

5-2. Turn the handle of

connector in a clockwise

direction, put the hole in

the middle of the table

through the pole. Turn the

table in a clockwise

direction to tighten and in a

counter-clockwise

direction to loosen.

Note: If table can not be

tightened, turn the handle

of connector in a counter-

clockwise direction a little,

then turn the table in a

clockwise direction to

tighen.

6. Attach reflector stud (FF)

and three washers Ø8 (GG)

to screen cover. Tighten the

reflector studs.

7. Attach head assembly to

post.

7-1. Unscrew four stainless

steel bolts (LL).

7-2. Load head assembly

by inserting hose into post.

Insert head assembly into

post. Control knob should

be above decal on post.

Attach head assembly to

post, and loosely install

four stainless steel bolts.

Tighten bolts securely.

8. WARNING: Remove

protective cover before

assembling.

Note: If necessary for

proper alignment of

reflector sections, loosen

each bolt prior to further

assembly and retighten

after sections are aligned.

Note: If table cannot be

tightened, turn the handle

of connector in a counter-clockwise direction a little,

then turn the table in a clockwise direction to tighen.

9. Reflector plate assembly:

9-1. Slide two reflector

panels together.

Insert one screw M6 X 10

(II). Slide one washer Ø6

(HH) over threaded end

of screw M6 X 10 (II) and

screw on cap nut (JJ)

loosely.

9-2. Slide reflector plate

onto reflector panels.

Insert one screw M6 X 10

(II). Slide one washer Ø6

over threaded end of

screw M6 X 10 (II) and

screw on cap nut (JJ)

loosely. Repeat

procedure to complete

the assembly of all four

sections. Fully tighten all

of the screws in the

rolled edge.

10. Support heater. Slide

three washers washer

Ø8 (GG) over threaded

end of spacer. Locate

reflector assembly on 3

studs. Install three

washers Ø8 on studs

and securely tighten

wing nuts (KK) but do

not overtighten.

11. Connect hose and

regulator to cylinder. The

propane gas and cylinder

are sold separately.

Every part of the heater

shall be secure against

displacement and shall be

constructed to maintain a

fixed relationship between

essential parts under

normaland reasonable

conditions of handling

and usage. Parts not permanently secured shall be designed

so they cannot be incorrectly assembled and cannot be

improperly located or misaligned in removing or replacing

during cleaning or other servicing.

Use a standard 20 lb. propane cylinder only (approximately

12.2 in. / 31cm. in diameter and 17.9 in./ 45.5cm high).

Use this heater only with a propane vapor withdrawal supply

system. See chapter 5 of the standard for storage and

handling of liquefied petroleum gas, ANS/NFPA 58. Your local

library or fire department should have this book. Storage

of an appliance indoors is permissible only if the cylinder

5-1

D

E

CC

5-2

Tighten

Loosen

6

C

FF

GG

7-1

7-2

8

B

A

9-1

TT

JJ

HH

II

JJ

HH

II

9-2

TT

10

KK

GG

11

Standard 20 lb. tank

17.9in. / 45.5cm

12.2in. / 31cm

INSTALLATION INSTRUCTIONS

is disconnected and removed from the appliance. A

cylinder must be stored outdoors in a well-ventilated

area out of the reach of children. A disconnected cylinder

must have dust caps tightly installed and must not

be stored in a building, garage or any other enclosed

area. The maximum inlet gas supply pressure: 250 psi

/1750 kPa. The minimum inlet gas supply pressure:

25psi/175kPa. Manifold pressure with regulator provided:

11 inch W.C/ 2.74 kPa. The pressure regulator and hose

assembly supplied with the appliance must be used.

The installation must conform with local codes, or in

the absence of local codes, with national fuel gas code,

ANS Z223.1/NFPA54, natural gas and propane Installation

Code, CSA B149.1, or propane storage and handling code,

B149.2.

The knob on the LP tank must be closed. Make sure that

the knob is turned clockwise to a full stop. The cylinder

supply system must be arranged for vapor withdrawal.

Check that the control knob on the control unit is turned

off. Hold the regulator in one hand and insert the nipple

into the valve outlet. Be sure the nipple is centered in

the valve outlet. The coupling nut connects to the large

outside threads on the valve outlet. Hand-tighten the

coupling nut clockwise until it comes to a full stop.

Firmly tighten by hand only.

To Disconnect: Fully close the tank valve by turning

clockwise. Turn the coupling nut counterclockwise until

the regulator assembly detaches.

A dented, rusted or damaged propane cylinder may

be hazardous and should be checked by your cylinder

supplier. Never use a propane cylinder with a damaged

valve connection.

The propane cylinder must be constructed and

marked in accordance with the specifications for LP

gas cylinders of the U.S. Department of Transportation

(DOT) or the standard for cylinders, spheres and tubes

for transportation of dangerous goods and commission,

CAN/CSA-B339.

The cylinder must have a listed overfilling prevention

device.

The cylinder must have a connection device compatible

with the connection for the appliance.

The cylinder used must include a collar to protect the

cylinder valve.

Never connect an unregulated propane cylinder to the

heater.

12. Screw regulator

onto gas hose. Do

not cross-thread.

Tighten securely. Attach

regulator to cylinder.

Complete attachment.

13. Install cylinder.

WARNING:

• Do not store a spare LP-gas cylinder under or

near this appliance;

• Never fill the cylinder beyond 80 percent full;

• Place the dust cap on the cylinder valve outlet

whenever the cylinder is not in use. Only install

the type of dust cap on the cylinder valve that is

provided with the cylinder valve. Other type of

caps or plugs may result in leakage of propane.

LEAK CHECK

WARNING:

• Perform all leak tests outdoors.

• Extinguish all open flames.

• NEVER leak test when smoking.

• Do not use the heater until all connections have

been leak tested and do not leak.

Regulator / Cylinder

connection

Hose / Regulator

connection

1. Make 2-3 oz. of leak check solution (one part liquid

dishwashing detergent and three parts water).

2. Apply several drops of solution where hose

attaches to regulator.

3. Apply several drops of solution where regulator

connects to cylinder.

4. Make sure all patio heater and light valves are OFF.

5. Turn cylinder valve ON.

If bubbles appear at any connection, there is a leak.

1. Turn cylinder valve OFF.

2. If leak is at hose/regulator connection: tighten

connection and perform another leak test. If bubbles

continue appearing, the hose should be returned to

the place of purchase.

12

13

INSTALLATION INSTRUCTIONS

Loading ...

Loading ...

Loading ...